Ever watched a busy yard slow down the moment rain starts pouring? That’s usually when forklift rain covers suddenly become the most discussed piece of equipment on site. Created to shield forklifts from rain, moisture, and constant weather exposure, forklift rain covers play a far bigger role than most operators expect.

Rain doesn’t just soak the ground. It sneaks into controls, damages electrical systems, speeds up corrosion, and puts excessive strain on forklifts. For warehouse and yard owners, this often translates into downtime, increased repair costs, and operators forced to work in uncomfortable conditions.

It is one of the main reasons you will find forklift rain covers and even something as simple as a forklift plastic cover during wet seasons in any facility. However, they give a solid level of protection, without getting in the way for daily use. In this blog, we’re breaking down why rain protection is so important for warehouses & yards and how National Forklift Covers keeps your operation productive when the weather wants something else!

Why Rain Accelerates Wear and Tear on Forklifts

While it doesn’t seem like much, rainwater exposure can be disastrous for your forklift in the long term. Control panels, wiring, and metal joints get infiltrated by moisture and corrosion, leading to electrical issues and downtime. Rust is more likely to develop in moist environments, which weakens important components and shortens the lifespan of your forklifts.

Operator areas get affected, too. Wet cushion surfaces become slippery, and the mould developing on your seats also remains, adding to uncomfortable forklift operation, difficult-to-the-touch controls, poor visibility, etc., which is unsafe and slows work progress. Luckily, forklift rain covers stop all of that and maintain the quality of the equipment by keeping it out of direct exposure. Reliable coverage by National Forklift Covers helps warehouses and yards reduce wear, skip costly repairs, and keep forklifts running smoothly throughout the rainy season.

How Warehouses Prevent Rain from Disrupting Outdoor Operations

The rainy weather need not limit the yard’s work. Warehouses that continue to thrive during rainy times depend on easy preventive steps to keep forklifts dry, operators content and product flowing consistently.

Let’s take a look at how warehouses keep their operations running:

Maintaining Forklift Usability During Rain

Forklift rain cover permits loading operation under a steady downpour. This keeps yards from experiencing unnecessary interruptions in routine operations.Protecting Sensitive Forklift Components

Protects steering columns, seats and electronics from rain, thus avoiding damage to panel mountings or electrical systems.Minimising Weather-Related Downtime

Warehouses avoid delays in shipping schedules and workflow by ensuring forklifts are protected from damage and operational issues.Enhancing Operator Comfort and Focus

The dry seat, better visibility and reduced exposure to rain create more comfortable and productive work conditions during wet shifts.

Why Temporary Rain Protection Is Ideal for Seasonal Operations

Rain is a seasonal problem?for warehouses and yards. Temporary Rainguard is a great way to protect forklifts during the rainy season without investing?in permanent awnings and expensive renovations.

Cost-Effective Seasonal Protection

Dependable forklift rain cover protects during the rainy season on a tight equipment protection budget.No Permanent Modifications Needed

These covers don’t need drilling, welding or structural alterations and can be easily transferred from one location to another.Quick On-and-Off Installation

Temporary rain covers can be installed and removed in minutes, allowing teams to quickly react to short-term severe weather.Flexible Fit Across Forklifts

Compatible with multiple forklift models, they are perfect for warehouses and yards that operate mixed fleets.

How to Choose the Best Forklift Rain Cover for Warehouses

While choosing the right rain cover, it’s not only about addressing the need to keep forklifts dry; it’s also about finding a solution that works within daily operations without causing new issues. Warehouses and yards require protection that?is practical, so easy to use in real working conditions.

Here are some factors to look out for:

Correct Fit for Forklift Model and Size

A well-fitted cover will keep dust and debris out and protect the controller from accidental spills without interfering with any of the controls. Specially designed?for specific forklift models, providing installation that is comparable to generic covers.

Durable, Weather-Resistant Materials

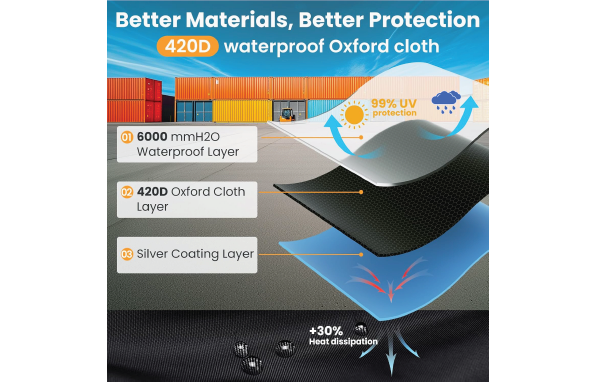

High-quality materials matter during long rainy days. A cover with strong, waterproof fabrics holds up better against repeated exposure and reduces the risk of leakage.

Easy Installation and Secure Attachment

Clear Visibility and Operator Access

Well-designed forklift rain covers preserve visibility and allow easy access to controls, which helps operators work safely and efficiently.

.png)